CrossTrack for Sheet Metal

CrossTrack for Sheet Metal

-

SQL-Server based

Using the widely-implemented MS SQL Server platform, Crosstrack delivers secure, multi-user access to stock, part, assembly and nest information.

-

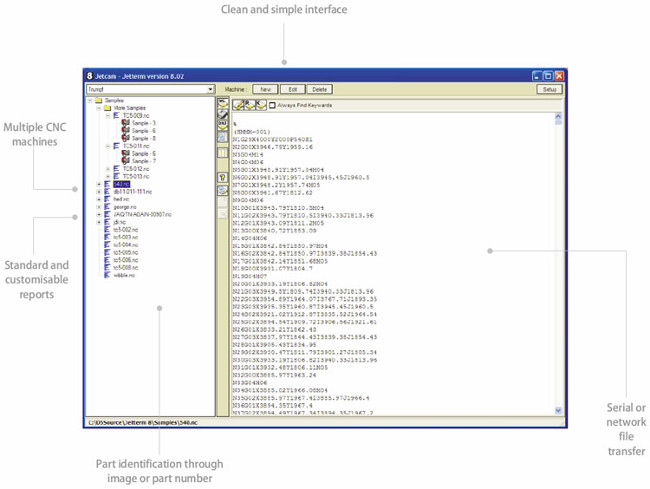

Simple interface and learning curve

Highly customisable interface allows you to show/hide as much as you want, on a per-user basis.

-

Security-first policy

Many of our customers work in secure, 'air-gapped' network environments, where no internet connection is required. ALL JETCAM products can work in these environments. Component and nest files employ high-level encryption for added security.

-

Market recognition

JETCAM products have won numerous awards because of their demonstrable return on investment. You can also view dozens of case studies spanning multiple industries.

Modular and scalable

CrossTrack for Sheet Metal also has a number of 'stations' available, allowing you to implement only the functionality required for a given user role.

-

Material Receiving Station (MRS)

Low-cost station for data entry of raw material.

-

Advanced Material Transfer Station (ATS)

As the Material Transfer Station, but also allows operators to view material stock and movement.

-

Material Transfer Station (MTS)

Logs material in and out of locations and used to track location/movement in real-time. Also available for iOS/Android.

-

Shop Floor Station (SFS)

Operator interface detailing nests to be cut, including features such as part scrapping and re-nesting, feedback to MRP, part identification on the nest, and much more.

-

General Purpose Information Station (GPIS)

Read-only viewing of key screens.

Additional Options

-

Alerts

Allow users to receive automated alerts for common issues or events such as nests being cut or reporting on automation.

-

Processes

Create unlimited operations and then link them to processes. These can then be associated with Kits as they travel through your facility. As each process is completed this is added to the traceability log, not only giving you location/life tracking, but also detailing every process by all staff.

-

MS Web Services Support

Provides communication via HTTP or .NET TCP for external systems such as MRP/ERP to send/receive information to CrossTrack for processes such as adding material stock, creating works orders, etc.

Features

- Ability to track material consumed by quantity (sheets), weight (fasteners, etc.), volume (paints, etc.) and length (rolls/coils).

- Track location of raw and processed materials

- One-click traceability report on raw materials or kits

- Fully automatic processing from CAD import through to nest generation

- Static, dynamic and progressive nesting

- Comprehensive shop floor scheduling

- Simple data exchange with MRP system, with option to use Microsoft Web Services

- Powerful user/user group control over all key functionality

- PC and mobile apps for material transfer and item information