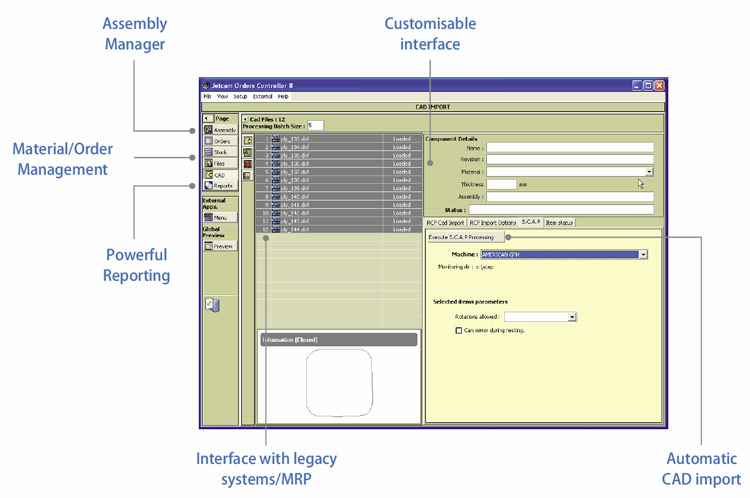

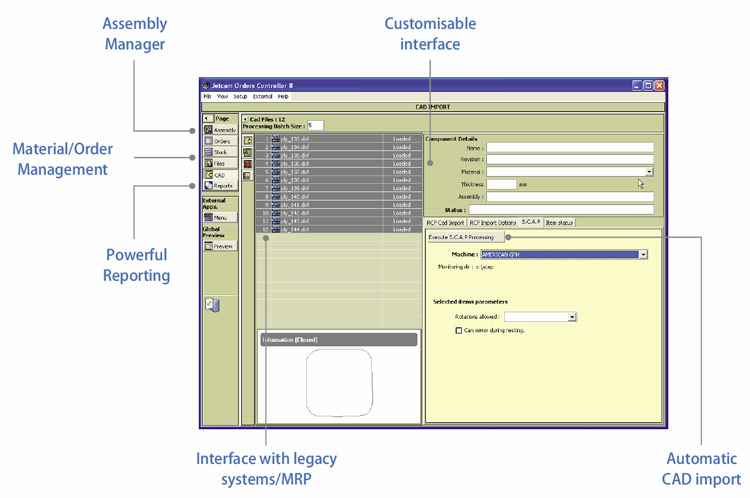

JETCAM Orders Controller Premium

JETCAM Orders Controller (JOC) simplifies the creation of orders for single components or component assemblies stored in the JETCAM Expert CADCAM system. JOC Premium provides a method of manipulating large numbers of geometry files, orders and assemblies as well as providing information about every aspect of a component or order at the click of a mouse.

|

JOC Lite

|

JOC Premium |

- Ability to remotely create orders within the JETCAM MRP Orders List

- Unlimited order lists/worksheets (e.g. by machine, operator, work day etc)

- Ability to place single or multiple part orders across any material or thickness for any machine on an ad-hoc basis

- Assembly Manager, including ability to create assemblies and subassemblies from directory structure

- Ability to replicate complete assemblies

- Quick modification of settings across order lists (e.g. quantities, machine, priority etc)

- One-click ordering of single/multiple components or complete assemblies

- Geometry/nest file previews with part select, zoom, measurement and DXF export/print capabilities

- Standard reports for nests, profiling and punching

- Ability to interrogate JETCAM Expert on status of active orders

- External CSV import of order lists for integration into legacy system such as MRP systems

- MRP Notifier tray app, allowing JOC to be notified by JETCAM system operator when next orders can be processed

- Multiple JETCAM system support

- Material management, allowing you to remotely administer JETCAM's Materials Stock List

- Ability to override JETCAM's default material usage parameters (such as sheet size, border size etc)

- JETCAM or custom PPI file support

- Process management for tracking of next manufacturing process for each job

- Linking of external applications

- Further customisation of user interface

- Customisable reports

- Component revision creation

- Automatic importing/processing of CAD files of different materials and thickness using both SCAP and RCP

- File manager RCP functions (e.g. one click retool part for different material/thickness/machine, mirroring etc)

- Ability to queue jobs to any available JETCAM system with RCP for automatic processing

- Support for composite technologies

- Ability to set up RCP functions for each machine

- Automatic assembly creation

- Assembly sequence support allowing for ply layup configuration (for composites)

- Ability to place nest on hold (e.g. for quality checks etc)

- Configuration for marking (composites)

|

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

|

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

|